KATOP | Innovative Dry Electrode Total Solution Empowers Accelerated Mass Production of All-Solid-State Batteries

Latest Information

After decades of rapid development, two main paths in the lithium battery industry have become clear: one is the dramatic expansion of market size, which has entered the TWh era; the other is the continuous reduction of manufacturing costs, leading to a decline in lithium battery prices year after year.

In the core field of power batteries, facing the rapid electrification trend sweeping the global automotive industry, traditional liquid-state lithium-ion batteries are gradually approaching their theoretical limits in terms of energy density, safety, and environmental friendliness. The lithium battery industry urgently needs a technological revolution to break through the current situation and meet the market's pressing demand for higher energy consumption and greater safety.

In this condition, all-solid-state lithium batteries have emerged as a major breakthrough in battery technology. Solid-state batteries, with their high energy density, excellent safety performance, long cycle life, low packaging requirements, and easy replacement, are considered one of the most promising directions for next-generation power batteries.

Solid-State Battery Market Prospects Are Flourishing

In the global wave of energy transformation, driven by policy support and market demand, solid-state batteries are becoming a focal point of competition in the global power battery technology landscape.

In recent years, countries and regions such as Europe, America, Japan, and South Korea have successively introduced policies to support the development of solid-state batteries and formulated long-term strategic plans. China first included solid-state batteries in its key development plan in 2020 and proposed accelerating industrialization. In 2023, it further proposed strengthening research on the standard system for solid-state batteries.

With the rapid development of the new energy vehicle industry, the market expansion of solid-state batteries has entered a "fast lane." It is expected that global demand for solid-state batteries will reach 17.3 GWh by 2025; by 2030, the market size could exceed 200 GWh, with an estimated compound annual growth rate of 65.8% between 2025 and 2030.

Developing Dry Electrode Whole Line Solutions to Boost Industrialization of Solid-State Batteries

In the research and production process of solid-state batteries, the preparation processes for electrodes and solid electrolyte membranes are undoubtedly critical. Different process routes directly impact key performance indicators such as the thickness and ion conductivity of the solid electrolyte membrane.

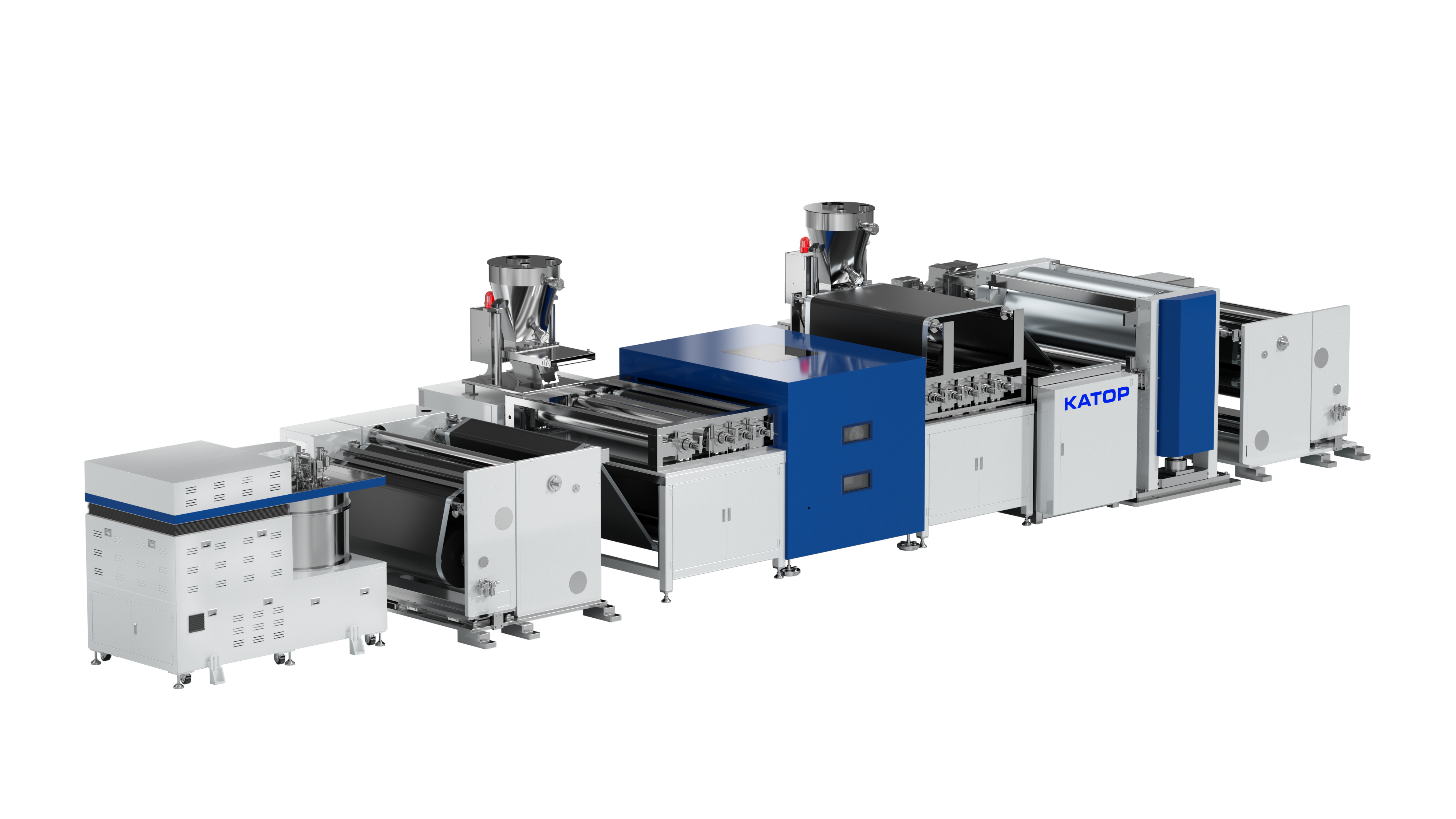

To address these challenges, KATOP established a dry electrode laboratory to explore and advance dry electrode process research together with its customers. It has introduced a total solution for dry electrode processes, empowering the industrial application of dry electrode technologies. Currently, the research team has successfully developed various dry film-forming methods and achieved the preparation of dry electrodes using graphite, NCM, and LFP.

KATOP's dry process flow primarily includes pre-mixing, coating, fibrillation, and self-supporting film formation. According to the characteristics of the dry process, it mainly involves mixing active particles, conductive agents, and binders; the conductive agent aggregates are dispersed on the surface of the active particles; binder secondary particles are cut into primary particles to form a fibrous network structure, which is then formed into a film and thinned via roller pressing to obtain a self-supporting film, finally bonded to the current collector.

For different process stages, KATOP provides corresponding equipment. For example, high-speed mixers, kneaders, and fluidized mills are used in the material preparation stage; segmented roller presses, continuous roller presses, and double steel belt roller presses are used in the electrode preparation stage. These devices ensure uniform mixing, material fibrillation, continuous film formation, and consistent thickness and surface density of the film.

Through nearly a decade of focused research and development in the field of dry electrode processes, KATOP has achieved multiple technological patent outcomes. To date, it has successfully delivered numerous dry processing machines to customers, and its exceptional process levels and product quality have been widely recognized.

"Global Expansion, Going Worldwide!" KATOP actively implements an "overseas" strategy, establishing overseas sales service teams and distributor networks in major markets globally. It is committed to providing outstanding after-sales services and customer experiences. KATOP is dedicated to delivering high-quality battery equipment products and after-sales services to both domestic and international customers, building a premium brand.

As a key supplier of lithium battery equipment, KATOP will continue to uphold the philosophy of "collaborative innovation and resource sharing," working closely with customers and partners throughout the supply chain to jointly promote the industrialization and mass production of dry electrode technologies. In the future, KATOP will continue to focus on the new energy sector, contributing to the ongoing progress and development of the global lithium battery industry.