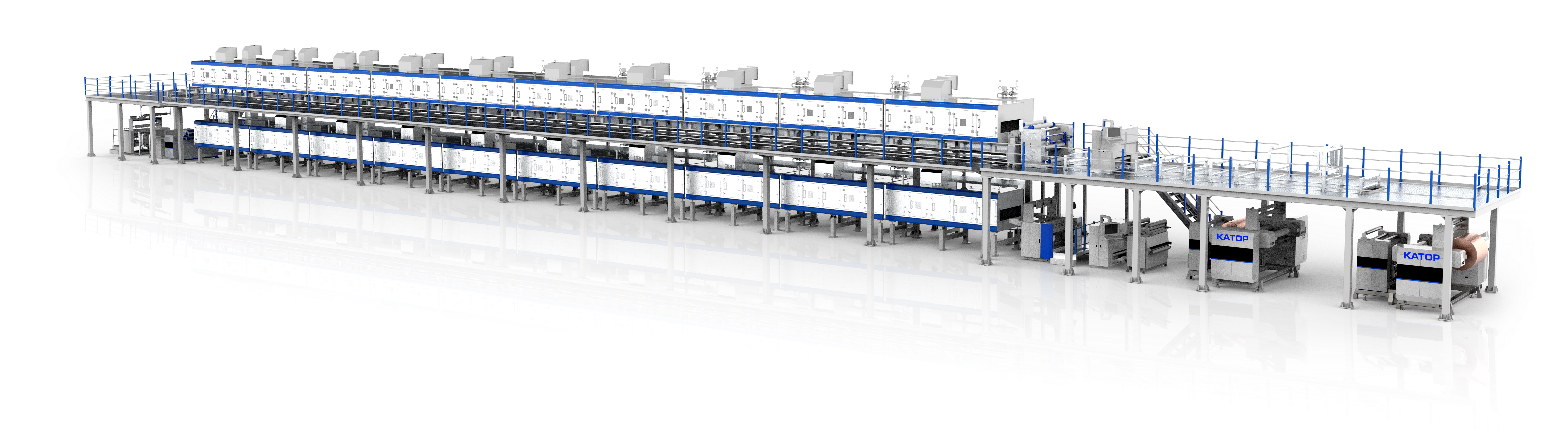

KATOP | Single/Double-Layer High-Speed Coater Aids in the International Leading Replacement of Lithium Battery Equipment

Latest Information

Since its establishment, KATOP has been dedicated to the R&D and manufacturing of coaters. After nearly two decades of relentless effort, the company's product line now covers single/double-layer high-speed coaters, single-layer extrusion coaters, separator coaters, double-layer gravure bottom coaters, laboratory coaters, and other types of coater series equipment, becoming one of the earliest enterprises in China to achieve internationalization of coating equipment.

Coaters, as non-standard products, have relatively high technical barriers, with foreign companies mainly concentrated in Japan and South Korea for a long time. Through the R&D of high-speed wide-width single/double-layer extrusion coaters, KATOP not only successfully broke the monopoly of Japanese and Korean companies in the Chinese high-end market but also further expanded into the international market. This achievement marks a new step forward in KATOP’s technological breakthroughs and global business expansion in the field of high-end coaters.

The high-speed wide-width single/double-layer extrusion coater from KATOP is equipped with features such as ultra-high speed, high precision, high intelligence, and efficient drying. In key performance indicators such as coating speed, coating width, surface density accuracy, automatic closed-loop control of surface density, efficient drying, tension stability, yield rate, and overall installation accuracy, it has reached international advanced levels.

Industry-Leading 150m/min Coating Speed

The coating process is a critical step in electrode sheet manufacturing, and coating quality is influenced by multiple factors, including the precision of the coating head, the stability of the equipment running speed, the accuracy of tension control during movement, and the uniformity of airflow and air pressure during drying.

In terms of coating speed, the current lithium battery coaters generally operate at around 80m/min, while KATOP's coater can run stably at up to 150m/min. Notably, in addition to leading in speed, KATOP's coater also shows significant improvements over conventional equipment in coating width, reaching 1450mm.

Surface Density Accuracy Stably Achieved ≤1%

In the coating process, the surface density accuracy of the electrode sheet directly affects the yield of the product. The high-precision adjustment and control system configured on KATOP's high-speed coater can stably achieve a surface density accuracy of ≤1%. This system is equipped with high-speed intermittent control technology, which can realize small-interval coating during high-speed coating while ensuring the length size accuracy of the electrode sheet and the thickness accuracy of the coating head and tail.

Intelligence and Automation Improve Efficiency

KATOP's high-speed coater adopts an Ethernet PLC control system and bus control mode, significantly enhancing the data transmission speed of the PLC, thereby significantly improving the operating speed of the equipment. Moreover, the data transmission accuracy of the PLC has also been significantly improved.

This type of coater is equipped with a multi-level deviation correction system, ensuring stable operation during the coating of 4.5μm copper foil or 8μm aluminum foil. At the same time, the winding/unwinding adopts a non-stop automatic reel change function, and the winding can achieve pre-cutting functions, meeting the combination of single-web undivided cutting and multi-web cutting. It uses an AGV material automatic conveying and loading/unloading system, achieving unmanned operation and continuous operation of the equipment, thus improving production efficiency.

Efficient Drying Significantly Reduces Energy Consumption

During the coating process, in addition to the coating accuracy and stability of the coater affecting the performance of the electrode sheet, the drying effect of the electrode sheet also has a direct impact on the quality of the electrode sheet.

KATOP's high-speed coater has adopted unique designs in aspects such as the drying box structure, pipeline structure, wind chamber structure, guide flow structure, nozzle structure, and exhaust system, ensuring the efficient drying performance of the equipment. The device can achieve a combination of various heating methods such as steam, thermal oil, and infrared, greatly reducing energy consumption.

Huge Potential in the Domestic Coater Market

In recent years, with the rapid development of the lithium-ion battery industry, the growth momentum of the coater market has been particularly strong. KATOP has been deeply involved in the lithium battery equipment industry, focusing on the R&D and manufacturing of high-speed coaters. With solid technical strength, high-quality products, and a complete after-sales service system, it enjoys a good reputation both at home and abroad. To date, KATOP has cumulatively delivered thousands of various types of coater equipment to domestic and international customers.

Looking to the future, KATOP will continue to focus on technological innovation in the coater industry, continuously improving the efficiency, reliability, and accuracy of coater products, while also increasing the level of domestication of the equipment, contributing more power to the development of the global new energy industry.