Latest Information

KATOP has been deeply involved in the new energy sector for nearly two decades, dedicated to optimizing the performance of lithium battery production equipment. In recent years, KATOP has launched a variety of lithium battery production equipment products, including electrolyte filling machine, lamination & stacking machine, and formation/capacity grading equipment. These products have not only gained widespread recognition for their stability and safety but also led industry trends through technological innovation and performance breakthroughs.

Innovative Thinking: From "Vertical" to "Horizontal" Filling

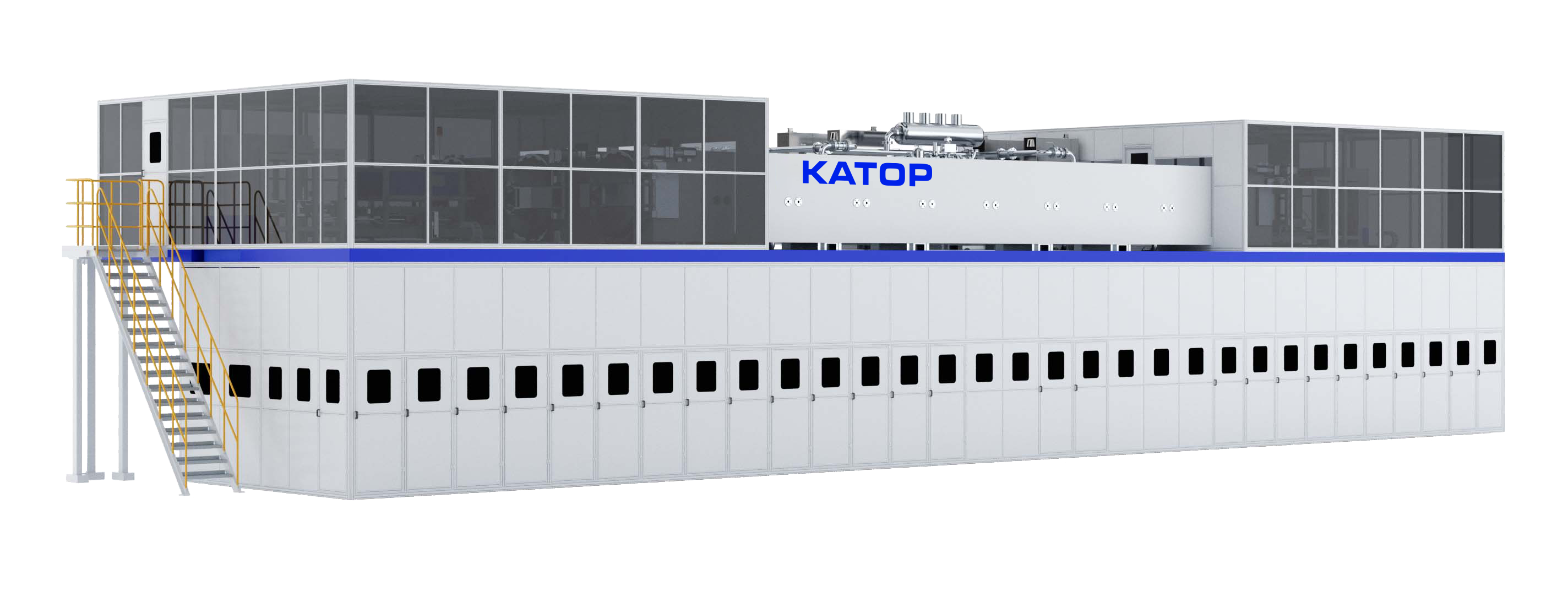

Under strict standards, KATOP rethought manufacturing logic and applied mature front-end process manufacturing technology to the design of electrolyte filling machine, innovatively developing horizontal filling machines. This significantly improved stability, precision, and other performance of equipment.

The horizontal filling machine integrates core technologies such as synchronous vacuum/filling, horizontal isobaric soaking chambers, and positive pressure recovery during soaking, greatly enhancing filling efficiency and earning high acclaim from customers.

Horizontal filling offers several advantages over other filling methods. In terms of production line optimization, horizontal filling allows for the extension or shortening of chambers, providing greater flexibility in production line layout according to specific customer capacity needs. Regarding safety, vertical movement of chambers during filling poses risks to the production line, which horizontal filling completely avoids.

In addition to the structural shift from "vertical" to "horizontal," KATOP's high-positive-pressure filling machine increases the pressure within the filling tank to 1.5MPa, reducing filling time by nearly 20%.

Classic Product, Embracing Digital Transformation

Two typical models of KATOP's horizontal filling machines can be considered classic examples of the company's horizontal filling equipment:

(1) 150PPM Cylindrical Battery Horizontal Isobaric Filling Machine

This machine adopts a 1st isobaric filling process, equipped with a slide rail assembly tray, dual filling stations, and a horizontal isobaric soaking chamber structure, offering higher space utilization and achieving synchronous vacuum/filling. The single-machine efficiency is 150PPM, with a filling volume CMK ≥ 1.67.

(2) 45PPM Square Aluminum Shell Horizontal Isobaric Filling Machine

This machine is used for 1st isobaric filling for prismatic aluminum shell batteries. It uses technologies such as synchronous vacuum/filling, horizontal isobaric soaking chambers, and positive pressure recovery during soaking. The single-machine efficiency is 45PPM, with a filling volume CMK ≥ 1.67.

Both filling machines can be optionally equipped with electronic scales and short circuit testers for automatic calibration, dual-level cups at the filling station, pressurization systems/vacuum systems, and whole-machine explosion-proof design, among other configurations. Customers can choose appropriate configurations based on their own needs.

KATOP actively embraces digital and intelligent trends, launching an automatic filling system that integrates automatic scanning, cleaning, Hi-pot testing, and other functions. Coupled with high-load, long-reach palletizing six-axis robots, this achieves high automation in the production line, bringing revolutionary changes to the lithium battery manufacturing industry.

Low-Risk "Horizontal" Filling Assists Lithium Battery Global Expansion

As the global expansion of the lithium battery industry accelerates, KATOP's horizontal filling equipment is favored in overseas markets due to its low safety risks. Lithium battery equipment must comply with local laws and regulations, including UL certification in the United States and CE certification in Europe. Combined with the complexity and diversity of products, the entire compliance process is highly uncertain, ranging from a few weeks to several years for approval.

KATOP is committed to promoting the overall high-quality global expansion of the lithium battery industry chain. By strengthening equipment structures and providing explosion-proof options, it simplifies the export approval process, demonstrating the competitiveness of Chinese intelligent manufacturing on the global stage.

To align with the trend of the overall global expansion of the lithium battery industry chain, KATOP has introduced structurally reinforced horizontal filling machines and added explosion-proof handling to its filling matrix products. All of KATOP's filling products can be equipped with explosion-proof options.

In the future, KATOP will continue to focus on core technology and product development, deepen cooperation with global partners, keep up with downstream product iterations and process innovations, respond to customer needs with faster response speed and higher customization capabilities, and create more efficient, intelligent, and personalized new energy equipment solutions. Through concrete actions, KATOP will assist in the arrival of the "Lithium Era."