Latest Information

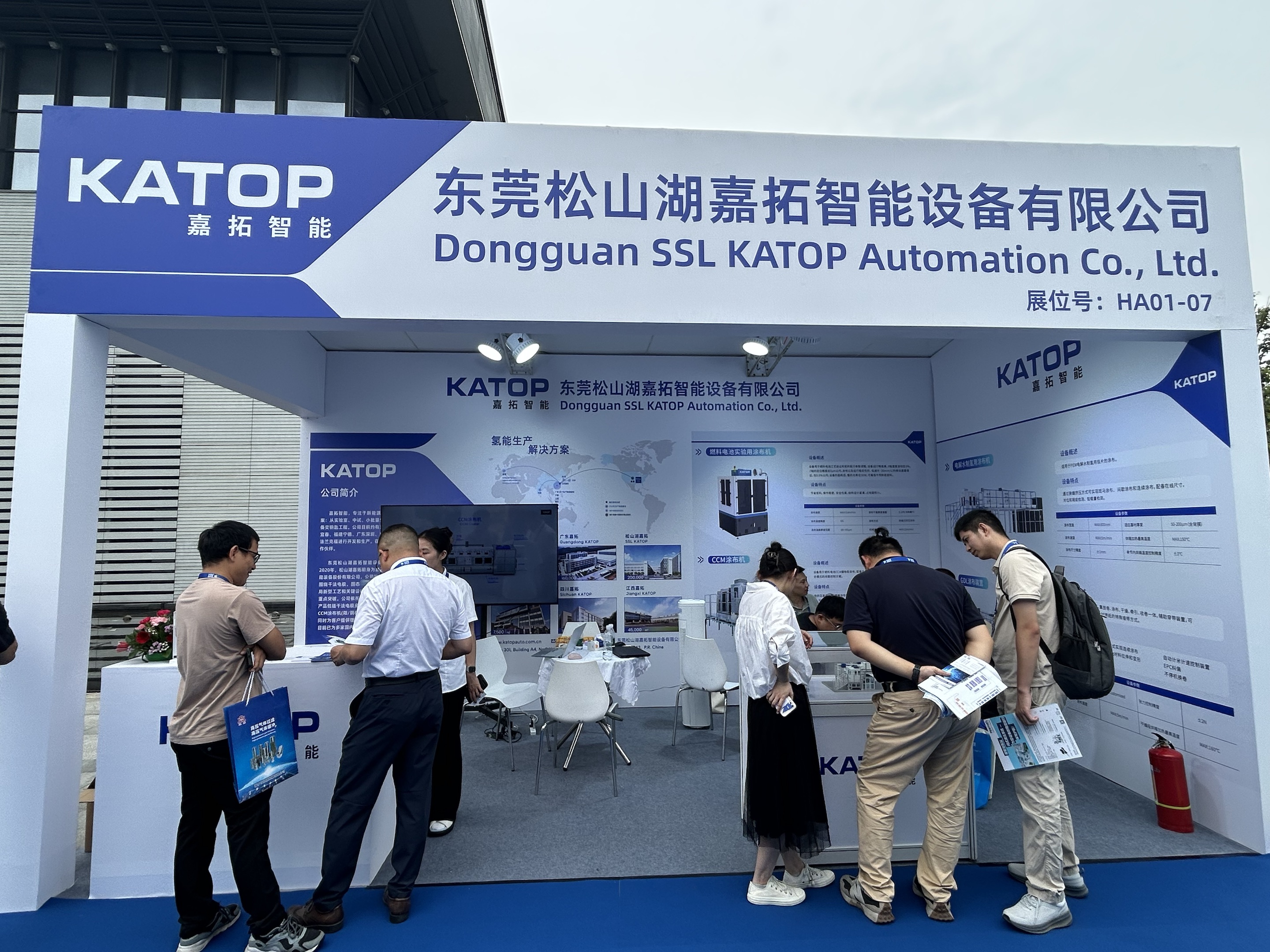

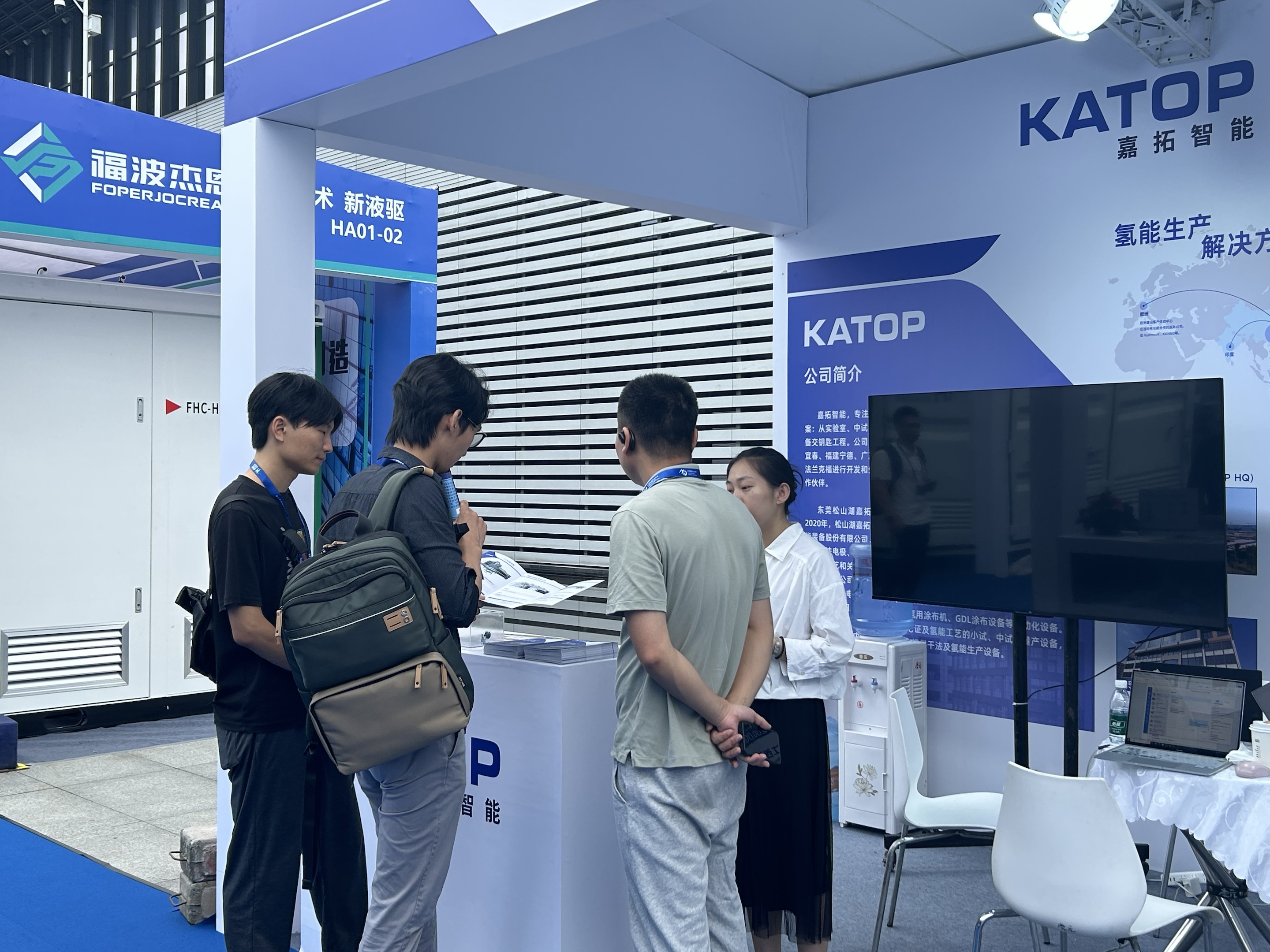

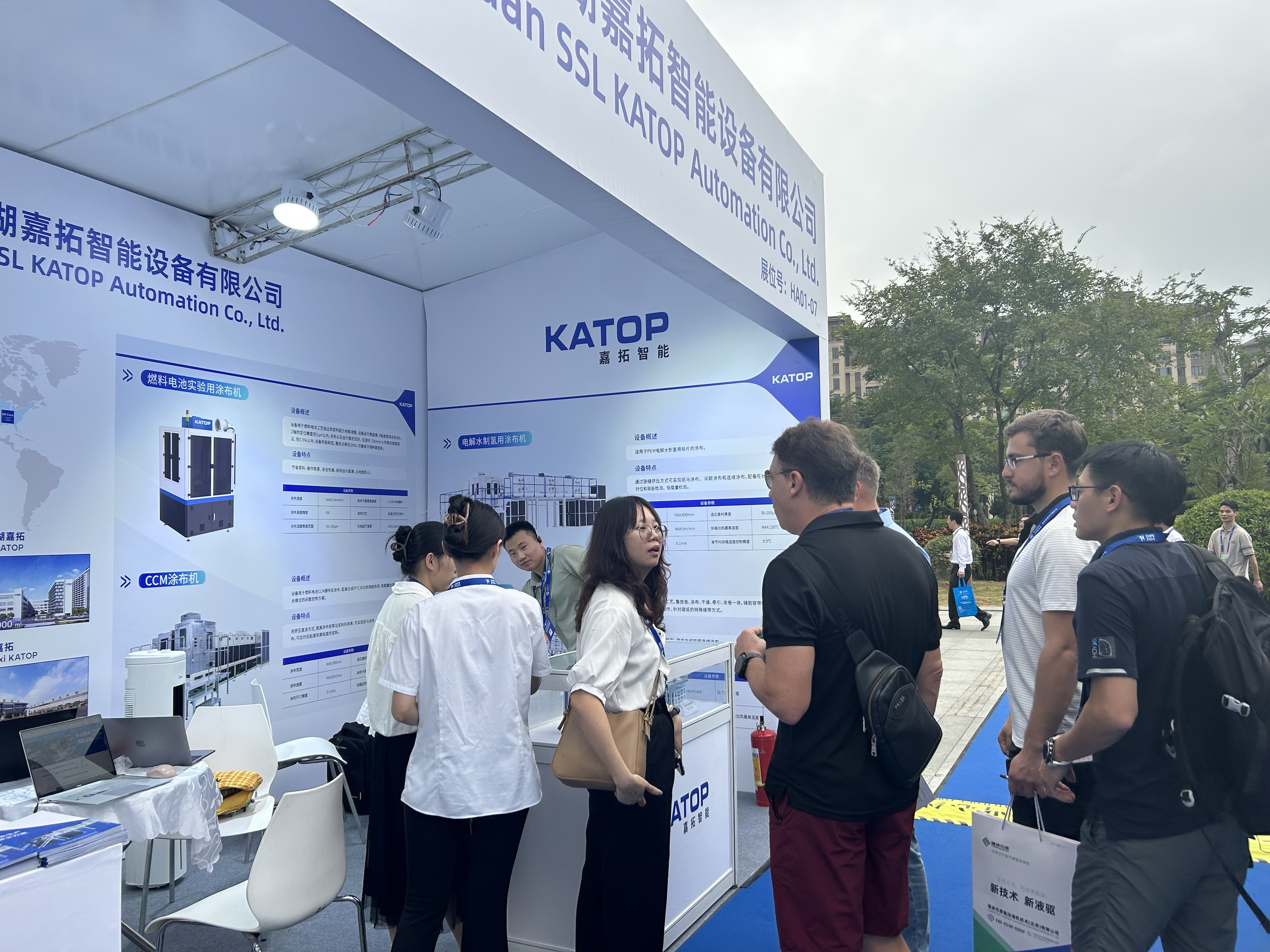

From October 18-20, The 8th International Hydrogen Energy & Fuel Cell Technology and Product Expo (CHFE2024) was grandly held in Foshan, Guangdong, once again making the hydrogen energy industry the focus of the sector. As a core equipment supplier for hydrogen energy, KATOP brought a series of advanced products, including its electrolytic water hydrogen production coating machine, fuel cell experimental coating machine, CCM coating machine (cathode), and GDL coating machine, to the exhibition. The company engaged with numerous attendees to explore the technical paths and industrial development trends of hydrogen energy and fuel cells.

During the exhibition, KATOP showcased its innovative achievements in the field of coating equipment and its contributions to the development of the hydrogen energy industry. From the precise coating of fuel cell membrane electrodes to the manufacturing of key components for electrolytic water hydrogen production equipment, the solutions provided by KATOP have not only significantly improved production efficiency but also ensured the high quality and stability of the products.

As a high-end intelligent equipment supplier integrating R&D, manufacturing, production, and sales services, KATOP focuses on specialized automated equipment for lithium battery core manufacturing and has developed multiple coating equipment models in emerging fields such as fuel cells. Currently, the company's representative products in the hydrogen energy field include CCM test machine flat coating, CCM Ca/An slit direct coating equipment, electrolytic water hydrogen production CCM slit direct coating equipment, GDL coating equipment (slit/knife/immersion), and alkaline diaphragm coating equipment, providing customers with comprehensive hydrogen energy coating one-stop solutions.

Through this participation, KATOP not only demonstrated its technical strength but also deepened its cooperative relationships with partners within the industry. Facing the global trend of energy transformation, KATOP will continue to strengthen its research and development capabilities, continuously break through the boundaries of hydrogen technology, provide more efficient and reliable solutions for every link in the hydrogen energy industry chain, and contribute to achieving green and sustainable development goals.